Sustainable fashion and shorter production chains, business development and collective investment: reinventing the textile and apparel industry with the entire sector, from sourcing to clothing.

This is the revolution led by Paul Boyer, one of the pioneers of ethical fashion in France, founder and CEO of LINportant, the first industrial manufacturing factory of organic & local “linen knitwear”.

Sandrine Maggiani: How does Linportant, an organic & local ” linen knitwear ” factory, contribute to reinventing the textile and clothing industry?

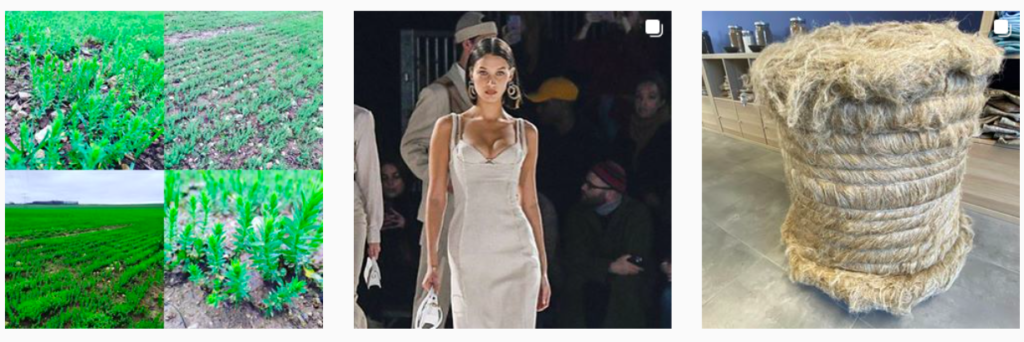

Paul Boyer: “Flax” is THE European textile fibre which is available just a few hours from Paris. LINportant is working to relocate the entire manufacturing process from the raw material to the final product.In Normandy specifically, where this industry has expertise and industrial equipment that allows us to produce the finest qualities of linen for clothing worldwide.

Yet it has long been impossible to industrially knit linen yarn in fine gauges. Today it is possible, and it starts with T-shirts. The factory applies a circular loom knitting technique and contributes to an eco-responsible ethical fashion (GOTS certified -Global Organic Textile Standard).

SM: For a brand, a designer, what are the advantages of linen knitwear and what type of products does it best adapt to?

PB: The circular linen knit is more breathable, which increases thermoregulation and is suitable for any season. The knitted fabric also provides the elasticity that makes linen knitwear as crease-resistant as cotton knitwear. Ideal for T-shirts, it is adapted to all types of fine knitwear, for women and men, sportswear : tunics, tank tops, tops, T-shirts, dresses…

Its ecological qualities also make it a very good choice for babies and children’s clothing. And soon also underwear. Linen knitwear can be easily declined in all the ranges of colors, in piece as well as in print.

courtesy of Linportant.fr image ©Jonas Gustavsson/Sipa USA/SIPA

courtesy of Linportant.fr image ©Jonas Gustavsson/Sipa USA/SIPA

SM: For the past few seasons, the demand for local and sustainable clothing has been strong in France. How can brands partner with LINportant and its textile re-localisation strategy ?

PB: Today, with the support of committed brands and industry players, we have launched “LinPossible” for the creation of a spinning mill in France.

But to achieve this goal, it is now up to the brands and designers who are increasingly mindful of respecting high environmental and societal, qualitative and ethical standards to push back the boundaries of linen, going beyond its stereotypical image of a seasonal, casual and creasable fabric to include it in their collections. And enable LINportant to develop an industrial tool for knitting and making garments 100% on a short and sustainable production chain.

SM: What is your vision of the textile and fashion industry in the near future?

PB: The crisis has highlighted both, the fragility of international supply chains and the resilience of local production facilities with a significant quantity of stocks.

We are seeing that industry players who were cooperating with their commercial partners will be better prepared to face the challenges collectively.

The acceleration of demand, already on the rise, for an eco-responsible and local textile offer.

In the midst of the crisis, the success of LINportant’s collaborative fundraising campaign has proven that demand for meaningful clothing is strong for consumers who lack offers from their favorite brands.

The increase in second-hand clothing, the popularity of which will enhance the quality and lifespan of the products, giving them a much better resale value.

We will continue to share with you the innovative visions of professionals to inspire you. Our consulting teams are at your side to support you. Let’s keep in contact